Press Release

|

NASA Spinoff 2008 |

Original source: http://www.aeroponics.com/NASA/50%20Years%20-%20Spinoff%202008%20.pdf |

|

Originating Technology/NASA Contribution

Experiments Advance Gardening at Home and in Space

AgriHouse's natural BEYOND Plant Amendment™ tested on the space shuttle and Mir protects plants In space and In gardens on earth {NASA Spinoff 2006).

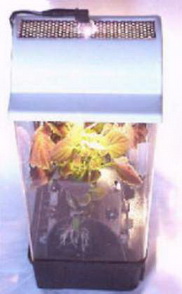

AgriHouse'e Aeroponic: Professional Benchtop Unit™ featuring true aeroponic growth developed by Richard J. Stoner under his NASA SBIR grants {NASA Spinoff 2006).

Tomato plants growing in the Plant Development Habitat (PDHab) at BioServe Space Technologies. For a recent experiment on the International Space Station, the PDHab was loaded into a Commercial Generic BioProccssing Apparatus, a temperature-controlled microgravity research platform that tias hosted a variety of experiments on numerous space shuttle, Mir, and ISS missions.

Tomato plants growing in the Plant Development Habitat (PDHab) at BioServe Space Technologies. For a recent experiment on the International Space Station, the PDHab was loaded into a Commercial Generic BioProccssing Apparatus, a temperature-controlled microgravity research platform that tias hosted a variety of experiments on numerous space shuttle, Mir, and ISS missions.

Aeroponics, the process of growing plants suspended in air without soil or media, provides clean, efficient, and rapid food product ion. Crops can be planted and harvested year-round without interruption, aind without contamination from soil, pesticides, and residue. Aeroponic systems also reduce water usage by 98 percent, fertilizer usage by 60 percent, and eliminate pesticide usage altogether, Plants grown in aeroponie systems have been shown to absorb more minerals and vitamins, making the plants healthier and potentially more nutritious.

The suspended system also has other advantages. Since the growing environment can be kept clean and sterile, the chances of spreading plant diseases and infections commonly found in soil and other growing media are greatly reduced. Also, seedlings do nor stretch or will while their roots are forming, and once the roots are developed, the plains can be easily moved into any type of growing rnedia without the risk of transplant shock. Lastly, plants tend to grow faster in a regulated aeroponic environment, and the subsequent case of transplant to a natural medium means a higher annual crop yield. For example, tomatoes are traditionally starred in pots and transplanted to the ground at least 28 days later; growers using an acroponic system can transplant them just 10 days after starting the plants in the growing chamber, This accelerated cycle produces six tomato crops per year, rather than the traditional one to two crop cycles.

These benefits, along with the great reduction in weight by eliminating soil and much of the water required for plant growth, illustrate why this technique has found such enthusiastic support from NASA. Successful long-term missions into deep space will require crews to grow some of their own food during flight. Aeroponic crops are also potential source of fresh oxygen and clean drinking water, and every ounce of food produced and water conserved aboard a spacecraft reduces pay load weight, decreasing launch costs and freeing room for other cargo.

Partnership

In 1997, NASA teamed with AgriHouse Inc., of Berthoud, Colorado, to develop an aeroponic experiment for use on the Mir space station. Richard Stoner II, founder and president of AgriHouse, had worked with aeroponics since the late 1980s, and developed and patented a method for aeroponic crop production. AgriHouse utilized the research direction of BioServe Space Technologies, a nonprofit, NASA-sponsored Research Partnership Center located at the University of Colorado in Boulder, to assist its efforts in developing its aeroponic technology for space flight (Spinoff 2006). BioServe has extensive experience in space flight, having flown payload experiments on 27 shuttle missions, 2 Mir missions (one being the a above-mentioned), and several missions on the International Space Station (ISS).